- HomeHome » Products » Bunching Machine » 0.03-0.64mm Copper Wire Cable Conductor Making Winding Stranding Buncher Machine

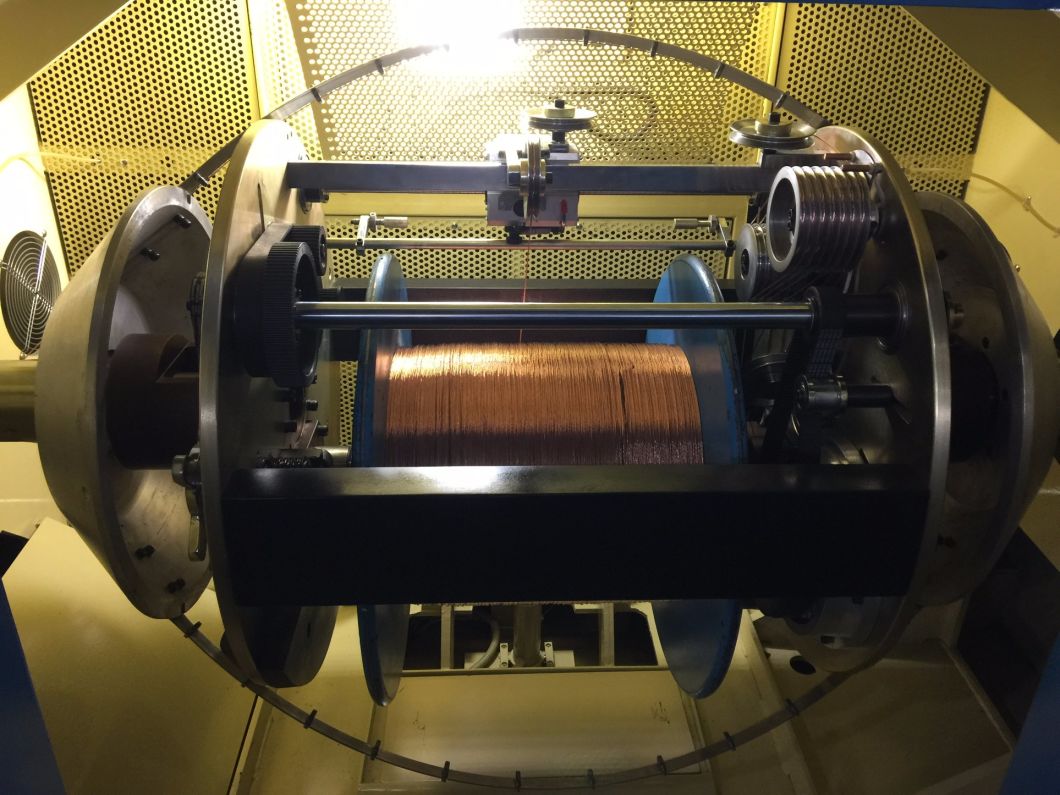

0.03-0.64mm Copper Wire Cable Conductor Making Winding Stranding Buncher Machine

Availability: -

12months

-

Electric

-

New

-

ISO, CE

-

12 Months

-

Automatic

Main performance parameters of FC-650B automatic high speed bunching machine (replace of the capstan wheel to change the lay length).

Usage:It is applied to the stranding of bare copper wire, tinned wire, copper covered aluminum wire, lacquer wire and alloy wire and so on. 1+6 may twist instead of bunching.

2.Diameter of single copper wire: φ0.16~φ1.04mm

3.Outer diameter of wire: φ0.84~φ3.2mm;

4.Cross section area: φ0.40~φ6mm2

5.Size of take up spool: φ630mm×430mm×φ125mm(according to client's drawings to make).

6. Maximum rotating speed:2000rpm(4000twist),in normal working speed1800rpm(3600twist).

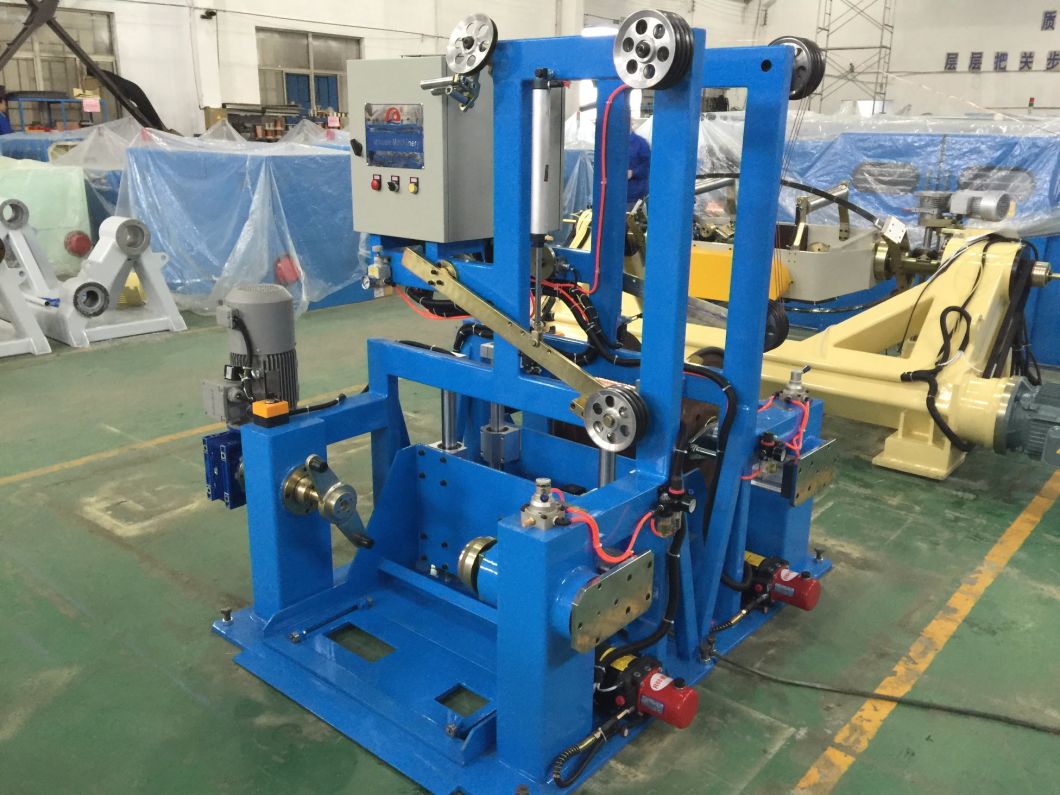

7.Type of traverse: φ30mm rolling ring traverse, winding pitch and breadth are adjustable.

8. Standard lay length: 34 section 11.6~100mm (enclose list of standard lay length).

9. Main motor: 7.5KW AC motor +frequency converter

10. Weight of copper load: about 400kg

11. Direction of strand: optional for right or left, only need to pull the reverse rod of the traverse by hands to adjust the lay-length, easy to operate.

12. Brake: electromagnetic brake for external break, automatic stop when wire reach setting meter.

13. Tension control: take up tension is controlled by magnetic powder clutch, PLC follows up and regulates tension constant tension.

14. Whole machine drive bearing:main shaft is from Sweden SKF bearing,other is adopted imported Japan NSK bearing.

15. Synchronization strap: with imported from American.

16. Spool from top to bottom: it is adopted manual hydraulic pump lifting.

17. Way of spindle lubrication: butter lubrication.

18. Index of noise: lower than 82dB

19. Dimension: 3300L×1450W×1650H(mm)

20. Weight: 4500Kg

21. Coating: Ral5015sky blue (may according to customer's requirements).

22. Package: simple waterproof packing

23. Direction: this machine is on your left, when you are in the face of front door, and pay-off on your right (may according to customer's requirements to make).

For more details, please feel free to contact me.

Main performance parameters of FC-650B automatic high speed bunching machine (replace of the capstan wheel to change the lay length).

Usage:It is applied to the stranding of bare copper wire, tinned wire, copper covered aluminum wire, lacquer wire and alloy wire and so on. 1+6 may twist instead of bunching.

2.Diameter of single copper wire: φ0.16~φ1.04mm

3.Outer diameter of wire: φ0.84~φ3.2mm;

4.Cross section area: φ0.40~φ6mm2

5.Size of take up spool: φ630mm×430mm×φ125mm(according to client's drawings to make).

6. Maximum rotating speed:2000rpm(4000twist),in normal working speed1800rpm(3600twist).

7.Type of traverse: φ30mm rolling ring traverse, winding pitch and breadth are adjustable.

8. Standard lay length: 34 section 11.6~100mm (enclose list of standard lay length).

9. Main motor: 7.5KW AC motor +frequency converter

10. Weight of copper load: about 400kg

11. Direction of strand: optional for right or left, only need to pull the reverse rod of the traverse by hands to adjust the lay-length, easy to operate.

12. Brake: electromagnetic brake for external break, automatic stop when wire reach setting meter.

13. Tension control: take up tension is controlled by magnetic powder clutch, PLC follows up and regulates tension constant tension.

14. Whole machine drive bearing:main shaft is from Sweden SKF bearing,other is adopted imported Japan NSK bearing.

15. Synchronization strap: with imported from American.

16. Spool from top to bottom: it is adopted manual hydraulic pump lifting.

17. Way of spindle lubrication: butter lubrication.

18. Index of noise: lower than 82dB

19. Dimension: 3300L×1450W×1650H(mm)

20. Weight: 4500Kg

21. Coating: Ral5015sky blue (may according to customer's requirements).

22. Package: simple waterproof packing

23. Direction: this machine is on your left, when you are in the face of front door, and pay-off on your right (may according to customer's requirements to make).

For more details, please feel free to contact me.

The company is a high-tech enterprise,specialize in design,development,manufacture,installation and debugging of wire and cable equipment. Products passed ISO9001:2008 quality management system certificate,and has the authorize of import and export.

QUICK LINKS

CONTACT US

No8 South road of WuSongJiang,Kunchan development zone,Jiangsu province.

Ms Rita: +86-15806265585 +86-18012661732 +86-15806265585 springzhou2009Copyright 2023 Fuchuan Electrical&mechanical Co.,ltd All Rights Reserved Technology By Leadong.com | Sitemap