English

- HomeHome » Products » Bunching Machine » Bare Copper Wire 0.03-0.52mm Twisting Double Twister Wire Making Bunching Machine

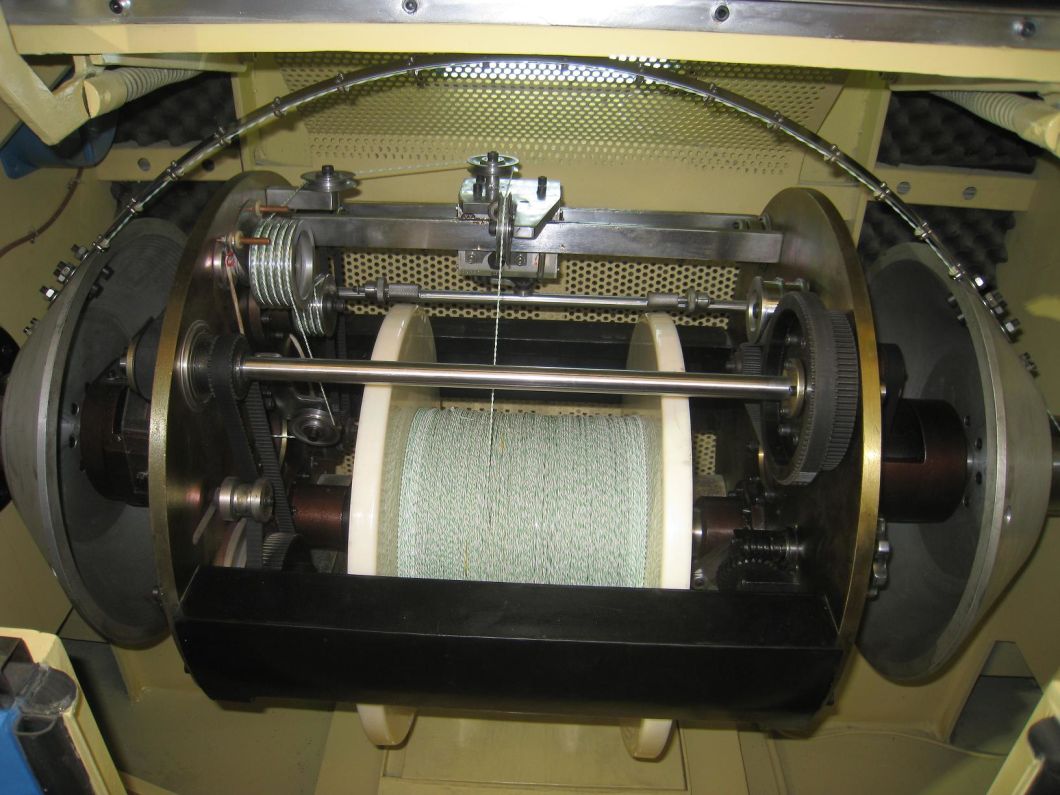

Bare Copper Wire 0.03-0.52mm Twisting Double Twister Wire Making Bunching Machine

Availability: -

12months

-

Bare Copper Wire, Tinned Wire, Silver Jacketd Wire

-

0.08mm-0.45mm

-

0.05mm2-2.5mm2

-

0.5mm-1.5mm

-

1.0mm-3.0mm

1. Characters:

With high rotation speed, with constant tension from empty bobbin to full bobbin, with superior quality for twist wire, the machine is driven by synchronization strap. Only need to change the capstan wheel to change the pitch, easy to operate.

2. Usage:

It is applied to the twisting of above 7 pcs of bare copper wires, tinned wires, silver jacketed wires and enamelled wires and double twisting for core wires.

3. Tech. Parameter:For more details, please contact me.Equipment model FC-500B FC-650B FC-650B-2 FC-800B Twisting usage Apply for the twisting of above seven pcs of bare copper wires,tinned wires,silver jacketed wires and enameled wires),double twisting for core wires. Single wire diaφ(mm) 0.08-0.45 0.15-1.04 0.37-1.7 0.37-1.7 Stranding section area 0.05-2.5 0.35-6.0 1.0-16 1.0-16 Core wire single wire diaφ(mm) 0.5-1.5 0.5-3.0 1.0-4.0 1.0-4.0 Core wire stranding outer dia(mm) 1.0-3.0 1.0-6.0 2.0-8.0 2.0-8.0 Pitch(mm) 6.3-52.3 11.6-100 20-160 23-147 Direction of lay Optional for right or left Take up bobbin(mm) Dia500 Dia630 Dia630 Dia800 Max rotating speed 3000rpm(6000TPM) 2000rpm(4000TPM) 1600rpm(3200TPM) 1600rpm(3200TPM) Main motor power 5.5kw 7.5kw 11kw 15kw Inverter power 5.5kw 7.5kw 11kw 15kw Tension control method Magnetic powder clutch+PLC+touchscreen,ensure the constant tension from empty to full bobbin Magnetic powder clutch 1.2kgf 5kgf 10kgf 10kgf Protection 1.wire inside and outside is broken,automatically brake/stop

2.The preset length is arrivedBrake mode Electromagnetic brake Traversing method Rolling wire with ring drive units,winding pitch and breadth are adjustable Operation mode Touchscreen operation Dimension(mm) 2680L*1250W*1500H 3300L*1550W*1800H 3400L*1600W*1800H 4600L*2000W*2000H

1. Characters:

With high rotation speed, with constant tension from empty bobbin to full bobbin, with superior quality for twist wire, the machine is driven by synchronization strap. Only need to change the capstan wheel to change the pitch, easy to operate.

2. Usage:

It is applied to the twisting of above 7 pcs of bare copper wires, tinned wires, silver jacketed wires and enamelled wires and double twisting for core wires.

3. Tech. Parameter:For more details, please contact me.Equipment model FC-500B FC-650B FC-650B-2 FC-800B Twisting usage Apply for the twisting of above seven pcs of bare copper wires,tinned wires,silver jacketed wires and enameled wires),double twisting for core wires. Single wire diaφ(mm) 0.08-0.45 0.15-1.04 0.37-1.7 0.37-1.7 Stranding section area 0.05-2.5 0.35-6.0 1.0-16 1.0-16 Core wire single wire diaφ(mm) 0.5-1.5 0.5-3.0 1.0-4.0 1.0-4.0 Core wire stranding outer dia(mm) 1.0-3.0 1.0-6.0 2.0-8.0 2.0-8.0 Pitch(mm) 6.3-52.3 11.6-100 20-160 23-147 Direction of lay Optional for right or left Take up bobbin(mm) Dia500 Dia630 Dia630 Dia800 Max rotating speed 3000rpm(6000TPM) 2000rpm(4000TPM) 1600rpm(3200TPM) 1600rpm(3200TPM) Main motor power 5.5kw 7.5kw 11kw 15kw Inverter power 5.5kw 7.5kw 11kw 15kw Tension control method Magnetic powder clutch+PLC+touchscreen,ensure the constant tension from empty to full bobbin Magnetic powder clutch 1.2kgf 5kgf 10kgf 10kgf Protection 1.wire inside and outside is broken,automatically brake/stop

2.The preset length is arrivedBrake mode Electromagnetic brake Traversing method Rolling wire with ring drive units,winding pitch and breadth are adjustable Operation mode Touchscreen operation Dimension(mm) 2680L*1250W*1500H 3300L*1550W*1800H 3400L*1600W*1800H 4600L*2000W*2000H The company is a high-tech enterprise,specialize in design,development,manufacture,installation and debugging of wire and cable equipment. Products passed ISO9001:2008 quality management system certificate,and has the authorize of import and export.

QUICK LINKS

CONTACT US

No8 South road of WuSongJiang,Kunchan development zone,Jiangsu province.

Ms Rita: +86-15806265585 +86-18012661732 +86-15806265585 springzhou2009Copyright 2023 Fuchuan Electrical&mechanical Co.,ltd All Rights Reserved Technology By Leadong.com | Sitemap